Contact us

Contact: Manager Wang

Mobile phone:+86 15063668532

Telephone: +86 0536 6053925

Fax:+ 86 536 6053915

location: Xiangzhou Industrial Park, Zhucheng City, Shandong Province, China

Short Description:

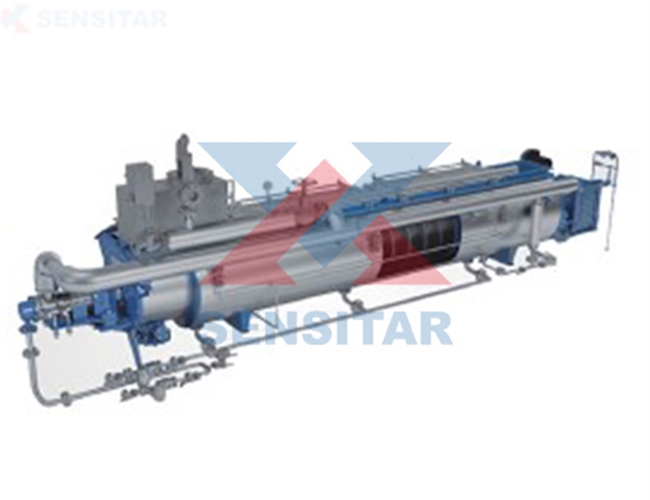

Product’s Introduction: Fish meal processing: The fish meal processing line mainly consists of a cooker, a press, a dryer, a cooler and a hammer mill etc. It is a modern design with easy operation, low energy consumption, low maintenance and long work life. The finished products are high quality fish meal and oil. Work-flow →crush →cooking →press →dry →cool → pack Simple process introduction The raw fish or fish steaks and waste are fed into crusher, and then continuously fed into t...

Product’s Introduction: Fish meal processing: The fish meal processing line mainly consists of a cooker, a press, a dryer, a cooler and a hammer mill etc. It is a modern design with easy operation, low energy consumption, low maintenance and long work life. The finished products are high quality fish meal and oil.

| Cooker Type | Capacity(t/h) | length(mm) | length(mm) | Width(mm) | Width(mm) |

| XFC0605 | 2-6-3-5 | 3350 | 1050 | 1200 | 4 |

| XFC0806 | 6.4-8.0 | 8250 | 1850 | 1850 | 12 |

| XFC0808 | 8.8-11.0 | 10200 | 1850 | 1850 | 14 |

| XFC1108 | 12.8-16.0 | 10900 | 2350 | 2200 | 20 |

| XFC1110 | 16.0-20.0 | 12800 | 2350 | 2200 | 23 |

| XFC1112 | 20.0-25.0 | 14850 | 2350 | 2200 | 27 |

| XFC1310 | 20.0-25.0 | 13050 | 2450 | 2200 | 32 |

| XFC1312 | 24.0-30.0 | 15050 | 2450 | 2200 | 36 |

| XFC1314 | 24.0-30.0 | 17050 | 2450 | 2200 | 40 |

| XFC1612 | 30.4-38.0 | 15150 | 3450 | 2400 | 40 |

| XFC1614 | 35.2-44.0 | 17150 | 3450 | 2400 | 47 |

| XFC1616 | 40.0-50.0 | 19150 | 3450 | 2400 | 55 |

Work-flow →crush →cooking →press →dry →cool → pack

Simple process introduction

The raw fish or fish steaks and waste are fed into crusher, and then continuously fed into the cooker by a conveyor.After the material is cooked, it is directly put into the press to get meal cake and oil. Meal cake goes into the dryer to dry.

World Best Selling Products Fish Meal Proessing High Quality Manufacturer

Short Description:

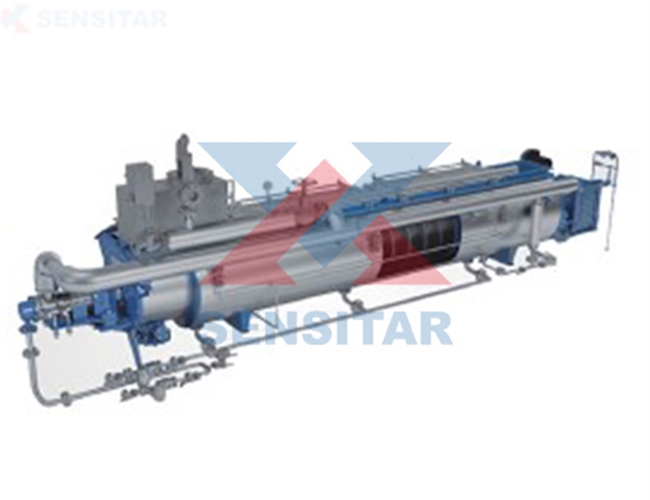

Product’s Introduction: Fish meal processing: The fish meal processing line mainly consists of a cooker, a press, a dryer, a cooler and a hammer mill etc. It is a modern design with easy operation, low energy consumption, low maintenance and long work life. The finished products are high quality fish meal and oil. Work-flow →crush →cooking →press →dry →cool → pack Simple process introduction The raw fish or fish steaks and waste are fed into crusher, and then continuously fed into t...

Product’s Introduction: Fish meal processing: The fish meal processing line mainly consists of a cooker, a press, a dryer, a cooler and a hammer mill etc. It is a modern design with easy operation, low energy consumption, low maintenance and long work life. The finished products are high quality fish meal and oil.

| Cooker Type | Capacity(t/h) | length(mm) | length(mm) | Width(mm) | Width(mm) |

| XFC0605 | 2-6-3-5 | 3350 | 1050 | 1200 | 4 |

| XFC0806 | 6.4-8.0 | 8250 | 1850 | 1850 | 12 |

| XFC0808 | 8.8-11.0 | 10200 | 1850 | 1850 | 14 |

| XFC1108 | 12.8-16.0 | 10900 | 2350 | 2200 | 20 |

| XFC1110 | 16.0-20.0 | 12800 | 2350 | 2200 | 23 |

| XFC1112 | 20.0-25.0 | 14850 | 2350 | 2200 | 27 |

| XFC1310 | 20.0-25.0 | 13050 | 2450 | 2200 | 32 |

| XFC1312 | 24.0-30.0 | 15050 | 2450 | 2200 | 36 |

| XFC1314 | 24.0-30.0 | 17050 | 2450 | 2200 | 40 |

| XFC1612 | 30.4-38.0 | 15150 | 3450 | 2400 | 40 |

| XFC1614 | 35.2-44.0 | 17150 | 3450 | 2400 | 47 |

| XFC1616 | 40.0-50.0 | 19150 | 3450 | 2400 | 55 |

Work-flow →crush →cooking →press →dry →cool → pack

Simple process introduction

The raw fish or fish steaks and waste are fed into crusher, and then continuously fed into the cooker by a conveyor.After the material is cooked, it is directly put into the press to get meal cake and oil. Meal cake goes into the dryer to dry.